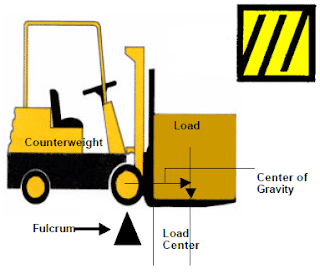

A forklift is counterbalanced and operates on a teeter-totter principle. A load on a beam (the forks) supported by a fulcrum (the front wheels) is counterbalanced by a weight on the other end of the beam (the forklift body and counterweight built into it). Forklifts are designed and manufactured deliberately unbalanced! The load of the forks must be balanced by the weight of the lift truck in order for this principal to work. We need a proper load to balance our “teeter-totter”.

You balance at both ends! A properly loaded lift truck does not exceed the rated capacity of the truck as listed on the trucks data plate.

Whether a forklift will safely carry a load or will tip forward can be determined by comparing the “moment” (a tendency to produce motion) of both the load and the forklift. Moment equals the distance from the fulcrum to the center of gravity (the point where all the weight is concentrated) times the weight.

Moment is the distance measured from the point at which the truck will tip over to the objects line of action.

Example: an evenly distributed 36” wide load on the forks has a center of gravity that is 18” from the face of the forks1. If the load weighs 4000 pounds then the load moment will be (18” x 4000 lb.) = 72,000 inch-pounds.

If the “moment” of the forklift is greater than or equal to the 72,000 inch pounds of the load then the forklift will safely carry the load. Forklifts have a capacity plate to tell the user what loads are safe to lift. If the plate says the capacity is 30,000 pounds or less then that capacity is rated for a load with a center of gravity 24” from the face of the forks. If the forklift capacity is greater than 30,000 pounds then the label will rate the load at a 36” or 48” center of gravity since larger forklifts usually lift physically larger loads.

Using the example and capacity plate above, a forklift rated at 5000 pounds would safely lift a load with a moment of up to (24” X 5000 lb.) = 120,000 inchpounds. In this case the load above would be safe to lift.

However if the 4000 pound load was 66” wide, the load moment would be (33” X 4000 lb.) = 132,000 inch-pounds which would be greater than the moment of the

However if the 4000 pound load was 66” wide, the load moment would be (33” X 4000 lb.) = 132,000 inch-pounds which would be greater than the moment of theforklift. The forklift would tip forward.

As the load is raised, it becomes possible for the forklift to fall to the side as well as tip forward. The operator must consider the center of gravity of the forklift and load together. This combined center of gravity moves as the load is moved and as the forklift travels over surfaces that are rough or inclined.

Forklifts have a “stability triangle”. The sides of the triangle as shown in the illustration are formed by the center of each front wheel and the center of the rear wheel or at the center of the axle if there are two rear wheels. A vertical line extending from the center of gravity of the vehicle-load combination must be inside of the stability triangle to prevent the forklift from tipping forward, falling sideways or dropping its load.

Tidak ada komentar:

Posting Komentar