Senin, 01 Agustus 2011

HOW FORKLIFTS SAFELY CARRY AND LIFT HEAVY LOADS

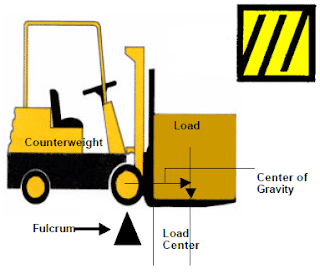

A forklift is counterbalanced and operates on a teeter-totter principle. A load on a beam (the forks) supported by a fulcrum (the front wheels) is counterbalanced by a weight on the other end of the beam (the forklift body and counterweight built into it). Forklifts are designed and manufactured deliberately unbalanced! The load of the forks must be balanced by the weight of the lift truck in order for this principal to work. We need a proper load to balance our “teeter-totter”.

You balance at both ends! A properly loaded lift truck does not exceed the rated capacity of the truck as listed on the trucks data plate.

Minggu, 31 Juli 2011

FORKLIFT, HEALTH AND SAFETY (OHS CODE)-01

Assessing hazards

Employers must assess their work sites to identify existing and potential hazards before work begins, and must eliminate or control the identified hazards. (OHS CODE, SECTION 7)

Appropriate equipment

Employers must ensure that forklift used in the workplace are of sufficient size, strength and design to perform the function for which they are intended. (OHS CODE, SECTION 12)

Manufacturer's specifications

Employers must ensure that forklifts are iperated and maintained in accordance with manufacturer's specifications, and that any modifications are done in accordance with manufacturer's specifications or specifications certified by professional engineer. (OHS CODE, SECTION 12)

FORKLIFT, HEALTH AND SAFETY (LEGISLATION)

Alberta's Occupational Health and Safety (OHS) Act. Regulations and Code have general and specific requirements related to the operation of forklifts.

Alberta's Occupational Health and Safety (OHS) Act. Regulations and Code have general and specific requirements related to the operation of forklifts.In many instances thr legislation sets out requirements for the safe use of "equipment" or "powered mobile equipment". All forklifts meet the definition of "equipment" and all powered forklifts meet the definition of "powered mobile equipment". Hence requirements relating to "equipment" and "powered mobile equipment" apply to forklift.

Langganan:

Komentar (Atom)